Depowdering of laser-melted metal parts: AMEXCI expands postprocessing capacity with two additional Solukon systems

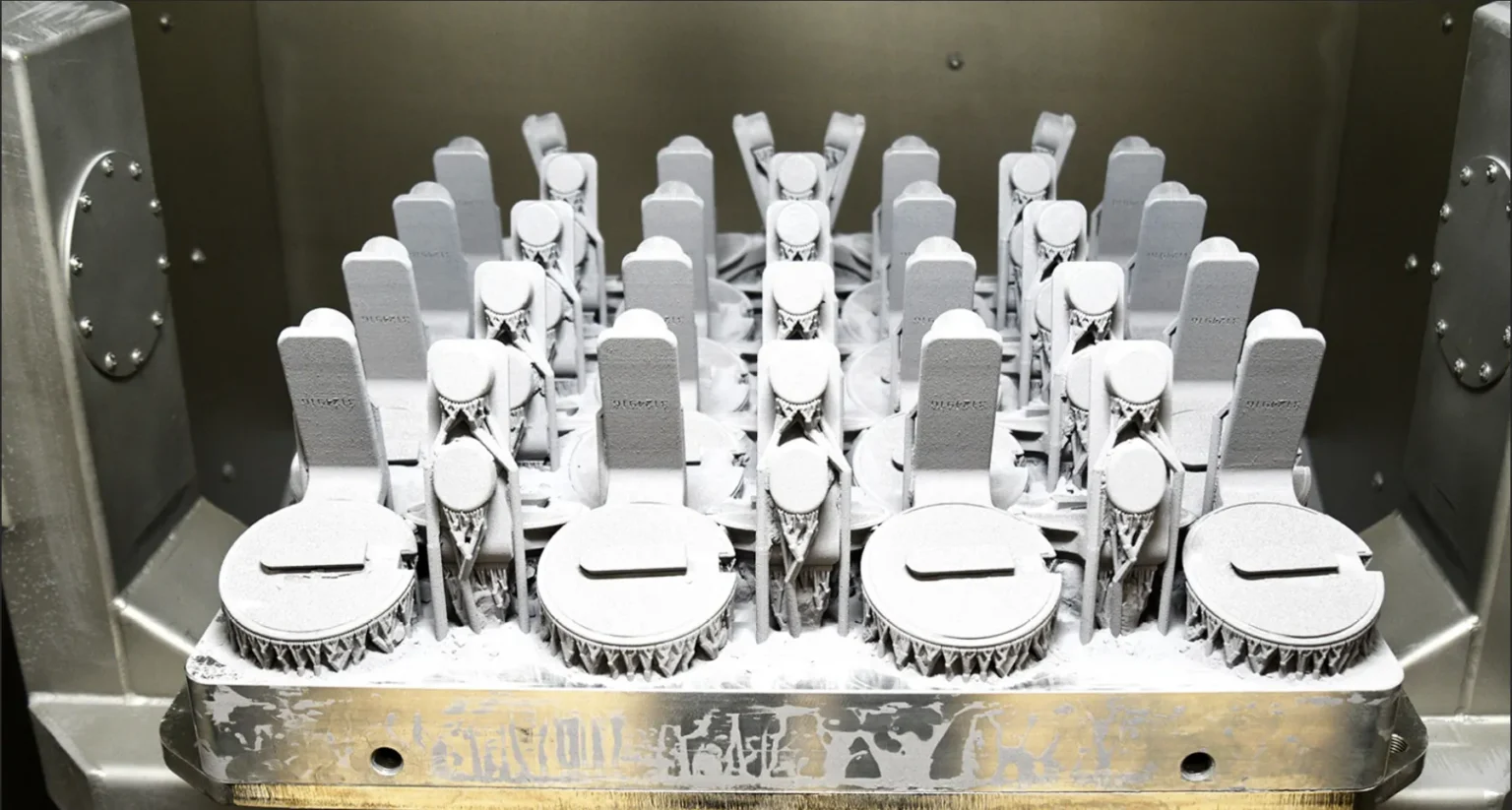

Figure 1: AlSi10Mg parts, printed in the NXG 600 System, depowdered in the SFM-AT1000-S by Solukon

AMEXCI now has three Solukon powder removal systems in use at different locations.

AMEXCI has strengthened its additive manufacturing operations with the installation of two additional Solukon depowdering systems, the SFM-AT350 for medium-sized parts and the

SFM-AT1000-S for large LPBF parts. These new units join the company’s existing Solukon portfolio, building on a successful collaboration that began in 2018 with the purchase of an SFM-AT300 which continues to operate reliably to this day.

New depowdering systems as perfect-fit addition to AM center Örebro

In May 2025 AMEXCI opened a new Additive Manufacturing facility in Örebro, Sweden. The new facility has been specifically designed to address growing requirements for efficiency, production capacity, and technological progress. With enhanced automation, improved material use, and shorter lead times, AMEXCI is now positioned to guide customers from early development through to full-scale serial manufacturing. For highest postprocessing demands the new Solukon depowdering systems SFM-AT350 and SFM-AT1000-S serve as a perfect-match addition to this high-end facility.

Consistent Depowdering Performance for multi-printer, multi-material production

When using the depowdering systems, AMEXCI benefits from the universality of Solukon systems. With two EOS M290 systems and two Nikon SLM systems (SLM 500 and NXG 600), AMEXCI depowders components from three different printers from two manufacturers.

For maximum process reliability, AMEXCI prefers single material use in their Solukon systems. The SFM-AT300 depowders components made of stainless steel (316l), the SFM-AT350 those made of titanium (Ti64), and the SFM-AT1000-S components of SLM printers made of aluminum (ALSI10Mg).

Every LPBF build job is postprocessed in a Solukon depowdering system, partly followed by an ultrasonic washer.

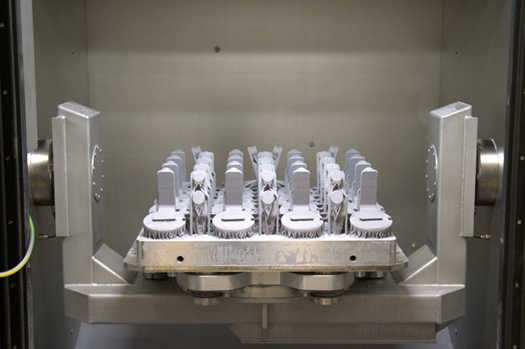

Figure 2: The Solukon systems at the AMEXCI facility

Why AMEXCI chose Solukon’s automated depowdering technology

When asked about the significance of Solukon in their AM processes, Andreas Petersen, Head of Production at AMEXCI, commented: “The Solukon system has been an essential piece of our AM workflow from the beginning. We chose the Solukon as for us, it was important to work with powder free parts as early as possible in the process. It is an important equipment for us to get parts free of powder for safer handling of parts for both our operators and our customers. It is simple to use, yet efficient. The cooperation with Solukon has been going well for 7 years now, with a team ready to help.

Figure 3: The SFM-AT1000-S depowdering system at the AMEXCI facility

What’s next with AMEXCI’s depowdering capabilities

Looking ahead, AMEXCI is evaluating the implementation of Solukon’s SPR-Pathfinder® software solution to further enhance efficiency. By digitally simulating optimal part motion based on the part-specific geometry, the company aims to improve depowdering predictability and streamline part-specific depowdering. This will help to remove powder from channels smaller than 1 mm, which currently still pose a major challenge, even more efficiently.

See in our AM facility video how automated depowdering with Solukon technology is applied at AMEXCI.

Figure 4: Glimpse insight the SFM-AT1000-S at AMEXCI

Figure 5: Glimpse insight the SFM-AT1000-S at AMEXCI

About Solukon

Solukon Maschinenbau GmbH is a German high-quality supplier of powder removal and processing systems for metal and polymer additive manufacturing. In 2015, Solukon presented the world’s first system for automated depowdering. Founded by Andreas Hartmann and Dominik Schmid, the Augsburg-based company has extensive experience in the development of AM systems and related peripheral equipment, and offers a full range of industrial powder processing systems. Since 2022, Solukon has also been offering the world’s first and unique intelligent software for automated simulation and (pre-)calculation of the depowdering of laser-melted metal parts, the SPR-Pathfinder®. Solukon products meet the highest functionality and safety standards and are approved for safe and reliable removal of tough-to-handle and reactive materials such as titanium and aluminum. Solukon has established itself as the market leader in the field of industrial powder removal with its powder removal systems for metal.

About AMEXCI

AMEXCI is a leading Additive Manufacturing company specialized in industrial metal 3D printing.

We operate two world class production facilities, one in Örebro, Sweden and one in Tampere, Finland. AMEXCIs head quarter in Sweden is a 4 700m2 facility specifically designed for Additive Manufacturing with the latest technology available on the market.

Our growing team of 40 employees possess deep knowledge in design, simulation, production, material analysis and post-processing, and have expertise in supporting our customers in industrializing Additive Manufacturing. In addition to our production capacity, we also provide comprehensive training programs and research services that cover several areas, including different high-performance materials and consultancy on evolving topics within additive manufacturing.

Our processes are certified in accordance with AS 9100D, ISO 9001, IATF 16949 and ISO 14001.

Our materials laboratory is accredited for ISO/IEC 17025 by SWEDAC, with accreditation number 10577. The accreditation includes tensile-, impact-, and hardness testing of metallic materials, using both ISO and ASTM standards. To see full accreditation scope please refer to SWEDAC.